Search This Supplers Products:casting partmullite sandcasting powderkaolinsilica solfoundry material

CASTING TOLERANCES BY DIFFERENT CASTING PROCESSES

time2022/05/26

- Casting tolerances for different casting processes

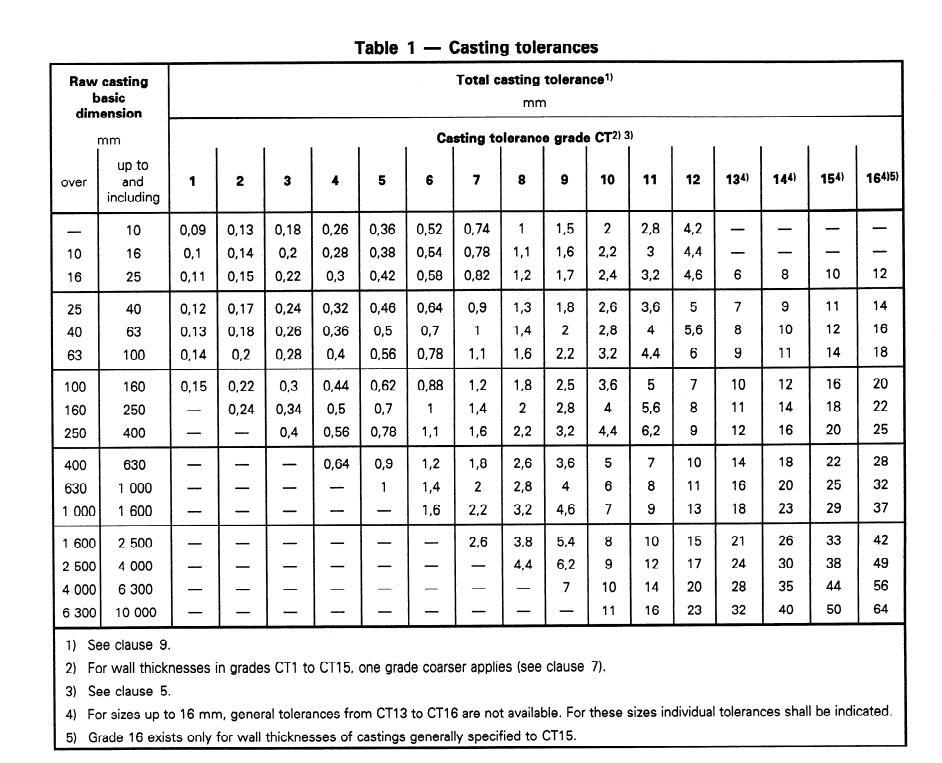

Dimensional tolerance is an important factor when we choose the casting process for the desired castings. In ISO 8062 (corresponding to China's GB/T6414-1999) standard documents, the tolerance levels of casting dimensions are clearly specified. Generally speaking, the investment casting and die casting have the high accuracy in dimension and that's why the investment casting process is also called precision casting. Here in the following you will see the general tolerances of castings by different casting processes.

Casting Tolerance and Capabilities at OBT Foundry | ||||||

|---|---|---|---|---|---|---|

| Casting Process | Annual Capacity / Tons | Main Materials | Casting Weight | Dimensional Casting Tolerance Grade (ISO 8062) | Heat Treatment | |

| Green Sand Casting | 6000 | Gray Cast Iron, Ductile Cast Iron, Cast Al, Brass, Cast Steel, Stainless Steel | 0.3 kg to 200 kg | CT11~CT14 | Normalization, Quenching, Tempering, Annealing, Carburization | |

| Resin Coated Sand Casting (Shell Casting) | 0.66 lbs to 440 lbs | CT8~CT12 | ||||

| Lost Wax Investment Casting | Water Glass Casting | 3000 | Stainless Steel, Carbon Steel, Alloy Steel, Brass, Aluminium, Duplex Stainless Steel, Cast Iron | 0.1 kg to 50 kg | CT5~CT9 | |

| 0.22 lbs to 110 lbs | ||||||

| Silica Sol Casting | 1000 | 0.05 kg to 50 kg | CT4~CT6 | |||

| 0.11 lbs to 110 lbs | ||||||

| Lost Foam Casting | 4000 | Gray Iron, Ductile Iron, Alloy, Carbon Steel, Stainless Steel, Brass, Al | 10 kg to 300 kg | CT8~CT12 | ||

| 22 lbs to 660 lbs | ||||||

| Vacuum Casting | 3000 | Gray Iron, Ductile Iron, Alloy Steel, Carbon Steel, Stainless Steel | 10 kg to 300 kg | CT8~CT12 | ||

| 22 lbs to 660 lbs | ||||||

| High Pressure Die Casting | 500 | Aluminium Alloys, Zinc Alloys | 0.1 kg to 50 kg | CT4~CT7 | ||

| 0.22 lbs to 110 lbs | ||||||

Casting Tolerances for Sand Castings

The casting tolerances are divided into Dimensional Casting Tolerances (DCT) and Geometrical Casting Tolerances (GCT). Our foundry would like to talk with you if you have special request on the required tolerances. Here in the following are the general tolerances grade we could reach by our green sand casting, shell mould casting and no-bake furan resin sand casting:

- ✔ DCT Grade by Green Sand Casting: CTG10 ~ CTG13

- ✔ DCT Grade by Shell Mold Casting or Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ GCT Grade by Green Sand Casting: CTG6 ~ CTG8

- ✔ GCT Grade by Shell Mold Casting or Furan Resin Sand Casting: CTG4 ~ CTG7

Casting Tolerances for Investment Castings

According to the different binder materials used for making the shell, the investment casting could be divided into silica sol casting and water glass casting. The silica sol investment casting process have better Dimensional Casting Tolerances (DCT) and Geometrical Casting Tolerances (GCT) than water glass process. However, even by same casting process, the Tolerance Grade will be different from each cast alloy due to their various cast ability. Our foundry would like to talk with you if you have special request on the required tolerances. Here in the following are the general tolerances grade we could reach both by silica sol casting and water glass casting processes separately:

- ✔ DCT Grade by Silica Sol Lost Wax Casting: DCTG4 ~ DCTG6

- ✔ DCT Grade by Water Glass Lost Wax Casting: DCTG5 ~ DCTG9

- ✔ GCT Grade by Silica Sol Lost Wax Casting: GCTG3 ~ GCTG5

- ✔ GCT Grade by Water Glass Lost Wax Casting: GCTG3 ~ GCTG5

Casting Tolerances for Shell Mold Castings

As we mentioned in the casting tolerance for sand castings, the shell mold castings have much higher accuracy and tighter tolerance than sand casting. Here in the following are the general tolerances grade we could reach by our shell mould casting and no-bake furan resin sand casting:

- ✔ DCT Grade by Shell Mold Casting or Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ GCT Grade by Shell Mold Casting or Furan Resin Sand Casting: CTG4 ~ CTG7

Casting Tolerances for Lost Foam Castings

Generally speaking, the casting tolerances of lost foam castings are better than sand casting, but worse than shell mold casting and no-bake casting processes. For our foundry, we basically could achieve the following casting grades. But we would like to talk with you the specific castings and then decide what numbers we can provide for you.

- ✔ DCT Grade by Lost Foam Casting: CTG9 ~ CTG13

- ✔ GCT Grade by Lost Foam Casting: CTG5 ~ CTG8

If the casting drawing or casting process document clearly requires inspection of all dimensions of the casting, all casting dimensions need to be inspected. This situation is usually the first part of the production of castings or the random sampling inspection process during mass production. In small batch production, it is sometimes required to inspect all dimensions of the casting.

In accordance with the requirements specified in the drawings or process documents, the dimensions of the castings need to be inspected for key control dimensions, dimensions with high accuracy requirements, and dimensions that are easily deformed and out of tolerance. This situation is usually applied to the control inspection of the dimensions of mass production on the production line.

Custom Cast Iron Casting Products