Search This Supplers Products:casting partmullite sandcasting powderkaolinsilica solfoundry material

-

OBT is committed to providing investment casting materials and equipments for 16 years. We can also provide more service according to customer's design requirement.

time2019/04/17

-

Foundry sand is divided into silica sand and non-siliceous sand according to different mineral compositions.

time2019/05/14

-

Colloidal silica is used as a binder with refractory grains such as alumina, aluminosilicates, fused silica and zircon. These systems are used for the casting of many types of metals.

time2020/03/02

-

What is the difference between die casting and investment casting?

time2020/04/15

-

Water treatment chemicals usage and silica gel colloidal silica for concrete

time2020/04/30

-

Lost wax investment casting precise foundry dewax machine

time2020/05/03

-

Several requirements in the production of precision casting equipment

time2020/05/09

-

What are the equipment used for precision casting.Each year OBT steel develop more than 300 sets new moulds.

Mean while OBT steel strictly follow the Non-disclosure Agreement for our Customers.time2020/05/11

-

For sand casting, mass-production factories should create conditions to adopt technologically advanced modeling and core-making methods.

time2020/05/14

-

The wax injection machine is widely used. In addition to industrial needs, it is also related to its corresponding characteristics.

time2020/05/23

-

The investment casting process is a kind of metal forming technology with a very long history. When we use a wax pattern for the casting,investment casting is also known as a lost wax casting process.

time2021/12/21

-

Do you know the comparative advantages of investment casting?

time2021/12/21

-

Frequently Asked Questions and Answers about Lost Wax Precision Casting Process

time2021/12/28

Publisherleena

-

Frequently Asked Questions and Answers about Lost Wax Precision Casting Process

time2021/12/28

Publisherleena

-

Introduction to Sand Casting:

Low tooling costs

Low or high volume requirements

Low part cost

Quick delivery or turn aroundtime2022/05/19

-

Casting tolerances for different casting processes

time2022/05/26

-

Casting manufacturing is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed mold and allowed to harden.

time2022/05/30

-

Ductile iron—also referred to as spheroidal or nodular iron—is actually a group of irons that exhibit high strength, flexibility, durability, and elasticity due to their unique micro structure.

time2022/05/31

-

High-pressure die casting is a manufacturing process where molten metal is pushed with a piston into a sealed cavity at high pressure and high speed.

time2022/06/06

-

Continuous Casting Process Explained | Types Of Continuous Casting

time2022/06/08

-

Low-pressure die casting is a method of production that uses pressure – rather than gravity – to fill molds with molten metal such as aluminum and magnesium.

time2022/06/09

-

OBT has always been a trusted partner in the foundry industry. We provide precision casting, die casting, sand casting, lost wax casting, forging and other processes.

time2022/06/10

-

There isn’t a one-size-fits-all approach in identifying the processes and casting production costs for your project. And ultimately, it depends largely on what type metal is used.

time2022/06/13

-

Investment casting is one of the most widely used processes in metal casting, especially for parts within the transportation and equipment industry.

time2022/06/14

-

3D printing is an interesting new development in the world of manufacturing. This tool has captured the attention of manufacturers as a way to reduce both time and cost, but the benefits and drawbacks vary depending on industry, project scope, and design.

time2022/06/20

-

Lost wax casting and investment casting are terms that are often used interchangeably, but there are few key differences that manufacturers and project managers should know.

time2022/06/21

-

When determining the ideal materials for your casting project, determining your need for ferrous vs. non-ferrous metals is a good place to begin. Raw material performance of the metal is influenced by the presence (or absence) of iron.

time2022/06/22

-

The requires more than a selection of tools and technology. In order to save money and ensure a high quality outcome, it’s important to carry out a detailed analysis of the parts being produced, along with their relationship to the machine and project in question. A number of factors need to be assessed, with efficient, accurate, and error-free CNC machining being dependent on procedural analysis and careful planning.

time2022/06/27

-

The most common materials for casting engine parts are iron base alloy steels.

time2022/06/28

-

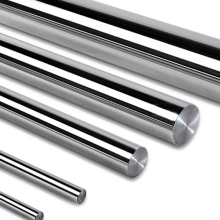

Accuracy 0.004mm

SGS,ISO,CE,Tuv certificates

Smooth surface roughness is Ra1.6

Titanium ,superalloy,aluminium ,stainless steel, etctime2023/03/30

-

What are the problems in processing titanium alloys?

time2023/04/06

-

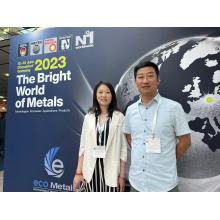

Qingdao O.B.T Co., Ltd. shone at the 2023 GIFA/NEWCAST/METEC/THERMPROCESS international casting exhibition in Dusseldorf, Germany. The company specializes in gas and steam turbine components, highlighting materials like titanium and high-temperature alloys. Exciting talks with global clients were a major highlight.

time2023/10/08

-

Qingdao O.B.T. proudly welcomes our Russian partners, who recently visited our facilities. This successful collaboration enhances our presence in the field of high-temperature alloys and titanium, solidifying our commitment to global excellence.

time2023/10/20

-

DZ22B alloy is a high-strength directionally solidified nickel-based superalloy with excellent high-temperature strength and medium-temperature properties.

time2023/10/20

-

General CNC processing generally refers to precision machining, CNC processing lathes, CNC processing milling machines, CNC processing boring and milling machines, etc.

time2023/11/09

-

High temperature alloys or high performance alloys are alloys that exhibit excellent mechanical strength and creep resistance at high temperatures, good surface stability, and resistance to corrosion and oxidation. They usually have an austenite-centered cubic crystal structure containing nickel, cobalt or nickel-iron alloy elements. The development of superalloys has been driven primarily by the aerospace and power industries.

time2023/11/10

-

NS315 is a nickel-based corrosion-resistant alloy with excellent corrosion resistance and mechanical strength at high temperatures. It is widely used in chemical industry, energy, aerospace and other fields. The alloy has a high chromium content, which can effectively resist oxidation and corrosion, and also contains appropriate amounts of nickel and iron elements, which enhance the alloy's toughness and heat resistance.

time2023/11/29