Search This Supplers Products:casting partmullite sandcasting powderkaolinsilica solfoundry material

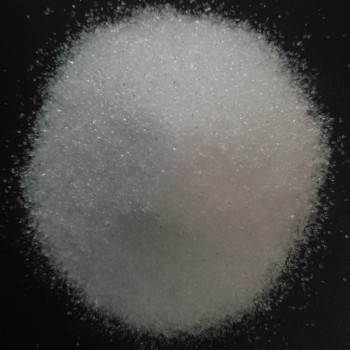

Precision casting use refractory materials high purity fused silica sand 20-50 mesh SiO2 99.7%

- group name

- Fused Silica Products

- Min Order

- 1 piece

- brand name

- OBT casting part Manufacturer

- model

- OBT-20-50

- Nearest port for product export

- Qingdao port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash, Escrow

- update time

- Thu, 30 Mar 2023 16:32:52 GMT

Paramtents

Color colorless or transparent

Appearance particle

Usage casting, binder,papper-making,concrete

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Fused Silica Products

Natural high purity quartz its microstructure at high temperature becomes the amorphous structure of the fused silica.

Is molten particles and silicon powder with high quality fused silica, through special crushing grinding process, the product high purity, controllable particle size distribution.

The main characteristics of fused silica are:

●High temperature resistance, good whiteness, melting point 1750 ℃.

●Excellent low electrical insulation.

●High hardness, high resistance to wear.

●Low expansion coefficient is low.

●Chemical properties of stability, in addition to react with hydrogen fluoride ether and alkali, does not react with any other material.

Photovoltaic materials, electronic materials, refractory materials, investment casting, high voltage electrical insulation materials, paint coating, silicone rubber, special ceramics, advanced materials, fine chemical industry, aerospace and other industries.

OBT has been manufacturing and supplying foundry and refractory materials for more than 20 years.